contact us

products

- Main Products

- IEC Test Probe

- UL Test Probe

- Material Flammability Tester

- IP Code Tester

- Impact Test Apparatus

- Security Testing Machine

- Lamp Cap Gauge Tester

- Lampholders Gauge Tester

- Plug & Socket Tester

- Electrical Safety Tester

- LED Test Instruments

- Environmental Test Equipment

- Instrument Accessories

- Weighing Sensor

- Others Testing Equipment

technical articles

Company News

Electrical Electronic Enclosure NEMA Standard 250

This material is derived from National Electrical Manufacturers Association for Electrical Equipment, NEMA 250, “Enclosures for Electrical Equipment (1000 Volts Maximum),” copyright 1997 by NEMA.. The information contained herein is not intended to be complete descriptions. Refer to NEMA Standard 250 for complete details.

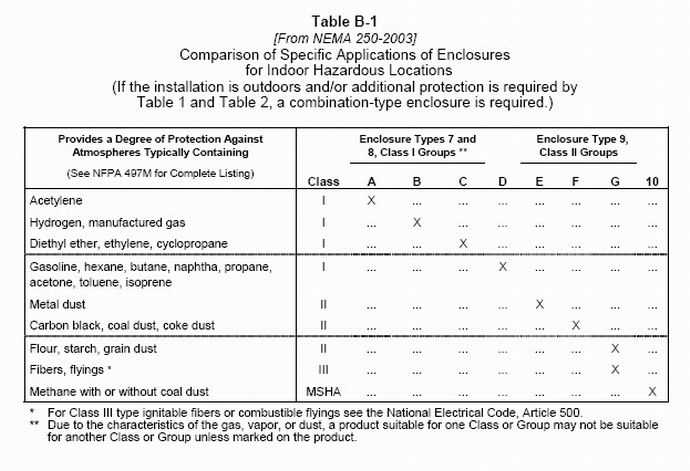

| TYPE | Application & Description |

| Type 1 | Applies to enclosures that are intended for indoor use primarily to provide some protection against contact with the enclosed equipment or locations where nontypical service conditions do not exist. |

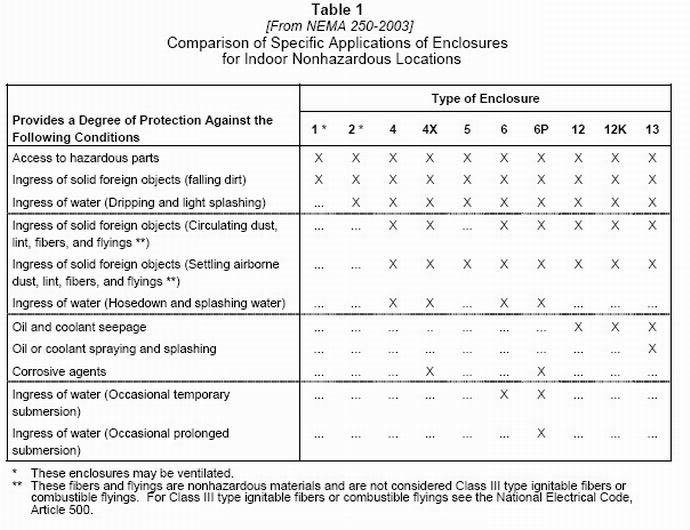

| Type 3 | For Enclosures that used for outdoor use primarily to provide some protection against windblown dust, rain, and sleet; resistant and undamaged by the formation of ice on the enclosure. |

| Type 3R | For enclosures that are used in the outdoors primarily to provide a protection against falling rain and sleet; undamaged by the formation of ice on the enclosure. |

| Type 4 | For enclosures that are used in indoor or outdoor use to provide a protection against windblown dust and rain, splashing water, and hose directed water; undamaged by the formation of ice on the enclosure. |

| Type 4X | For enclosures that are used for indoor or outdoor use to provide a protection against corrosion, windblown dust and rain, splashing water, and hose-directed water; undamaged by the formation of ice on the enclosure. |

| Type 6 | Submersible enclosures are suitable for application where the equipment may be subject to submersion. The enclosure design will depend upon the specified conditions of pressure and time. The enclosure will also remain undamaged by the formation of ice on the enclosure. |

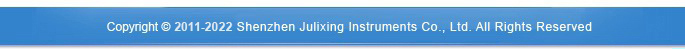

| Type 9 |

Hazardous location enclosures - Class II, Group E, F or G. These enclosures are designed to meet the requirements of the "Canadian Electrical Code" Part I for Class II hazardous locations, and CSA codes section 18 Class II Group E,f, and G. Class II Group E - atmosphere containing metal dust Class II Group F - atmosphere containing carbon black, coal, or coke dust. Class II Group G - atmosphere containing flour, starch or grain dust. |

| Type 12 | For enclosures that will operate primarily indoors. Industrial application are typical where the enclosures are oil tight. |

| Type 12K | These enclosures that will operate primarily indoors and have knockouts. Industrial application are typical where the enclosures are oil tight. |

| Type 13 | The cover is held in place with screws, bolts or other suitable fasteners, with a continuous gasket construction. The fastener parts are held captive when the door is opened. There are no holes through the enclosures for mounting or attaching controls inside the enclosure, and no conduit knock-outs or openings. Mounting feet, brackets, or other mounting means are provided. These enclosures are suitable for application to machine tools and other industrial processing machines where oil, coolants, water, filings, dust or lint may enter, seep into or infiltrate the enclosure through mounting holes, unused conduit knock-outs, or holes used for mounting equipment with the enclosure. |

These are not intended to be complete descriptions. Refer to NEMA Standard 250 for complete details.