contact us

products

- Main Products

- IEC Test Probe

- UL Test Probe

- Material Flammability Tester

- IP Code Tester

- Impact Test Apparatus

- Security Testing Machine

- Lamp Cap Gauge Tester

- Lampholders Gauge Tester

- Plug & Socket Tester

- Electrical Safety Tester

- LED Test Instruments

- Environmental Test Equipment

- Instrument Accessories

- Weighing Sensor

- Others Testing Equipment

technical articles

Company News

Impact Test of IEC

Remark: the following content is the general information of this test, for details, please refers to the endproduct standard.

(For EN60598-1: 2000; EN61558-1: 1997; EN60335-1: 1994; EN60065: 1998 standards.)

(For EN60598-1: 2000; EN61558-1: 1997; EN60335-1: 1994; EN60065: 1998 standards.)

1. Test goal:

Appliance shall have adequate mechanical strength and be so constructed as to be safe after such rough handling as may be expected in normal use.

2. Test apparatus

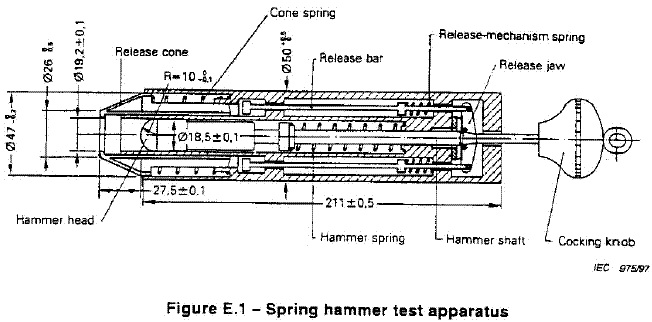

A spring-operated impact test apparatus specified in IEC 60068-2-63(replaced by IEC60068-2-75). (See illustration figure E.1)

3. Test procedure

a. The apparatus is held firmly against a rigid support.a. The apparatus is held firmly against a rigid support.

b. Three blows are applied to the exterior that protects hazardous live parts and is likely to be weak, including drawers in the pulled-out position, handles, levers, switch knobs and the like.

c. After the test, the sample shall show no damage in the sense of the end-product standard, in particular:

1). Live parts shall not have become accessible;

2). Insulating barriers shall not have been impaired;

3). The apparatus shall withstand the dielectric strength test as specified in the end-product standard.

4). Damage to the finish, small dents which do not reduce creepage distances and clearances below the specified value, and small chips which do not adversely affect protection against access to live parts or moisture are neglected.